The extensive use of glass and carbon fiber composites in manufacturing of modern aerospace components is raising the need for reliable, cost-effective NDT systems for the inspection of such components in the manufacturing stage.

The complexity of the new multilayered parts of complicated geometry with high curvatures and varying thicknesses and the requirement to inspect the parts on a 100% rate are posing serious challenges to such systems.

For example, stringer webs, flanges, edges, radii and chamfers as well as untrimmed part and parts drilled with holes must be completely inspected.

ScanMaster LS-200-COPA immersion scanners provide an efficient, automated solution for the ultrasonic inspection of Carbon and Glass-Fiber-Reinforced Polymer parts, such as skins, stringers, and spars.

The inspection is making use of multi-channel ultrasonic phased array (PA) technology, which is well proven for such applications.

• High flexibility, accommodating automated scanning of diverse parts such as skin, edge, radius and stringer in one system

• Easy part programming, including 3D contour following through intuitive Teach In tools, including import of CAD files

• High productivity

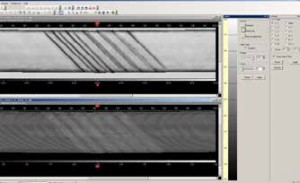

• Full A- Scan and C-scan imaging (2D and 3D)

• Defect representation and sizing in 3D presentation

• Compliance with Airbus and Boeing requirements

Korean

Korean